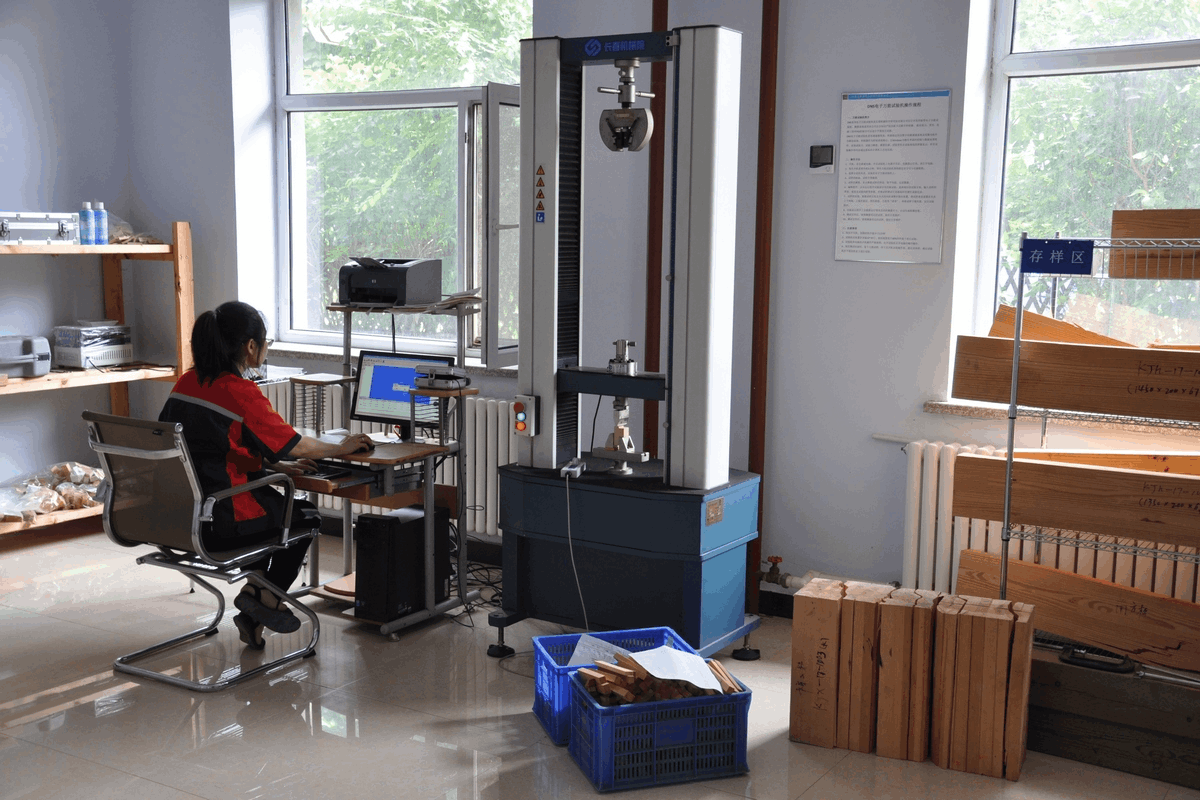

Adhesive Property Test

|

Using a water bath and a high-strength pressure cooker,conduct immersion peeling tests on wood component adhesives.

Role of Universal Testing Machines in Glulam Adhesive Testing Key Functions 1. Comprehensive Testing Capabilities

2. Adhesive Bond Quality Assessment

|

Testing Parameters 1. Standard Testing Procedures

2. Critical Measurements

Equipment Specifications 1. Machine Requirements

2. Testing Conditions

|

|